A stopper for every story

Tradition meets innovation, a stopper at a time.

Stand out with premium stoppers and elevate the consumer experience.

Find Your Style

From timeless classic to modern innovations, our stoppers suit all packaging styles. Whether you prefer minimalist elegance or bold opulence, we offer a diverse range —including entry-level cork stoppers, premium metal closures, GPIs, and innovative combinations– like wood and metal or our latest MAGNET top closures.

Solutions tailored to meet the needs of your brand

Recycled materials, added value and customization

Our stoppers combine premium, recycled materials like Zamac and Steel with full customization to enhance brand identity.

Designed for visual impact and shelf appeal, they deliver both: aesthetic value and functionality. With sustainable options and 100% custom designs, we craft unique closures that elevate every brand while accommodating every budget.

Premium Entry Level

Off-The-Shelf

T-Synthetic Cork

Metal Premium

3D

Materials Mix

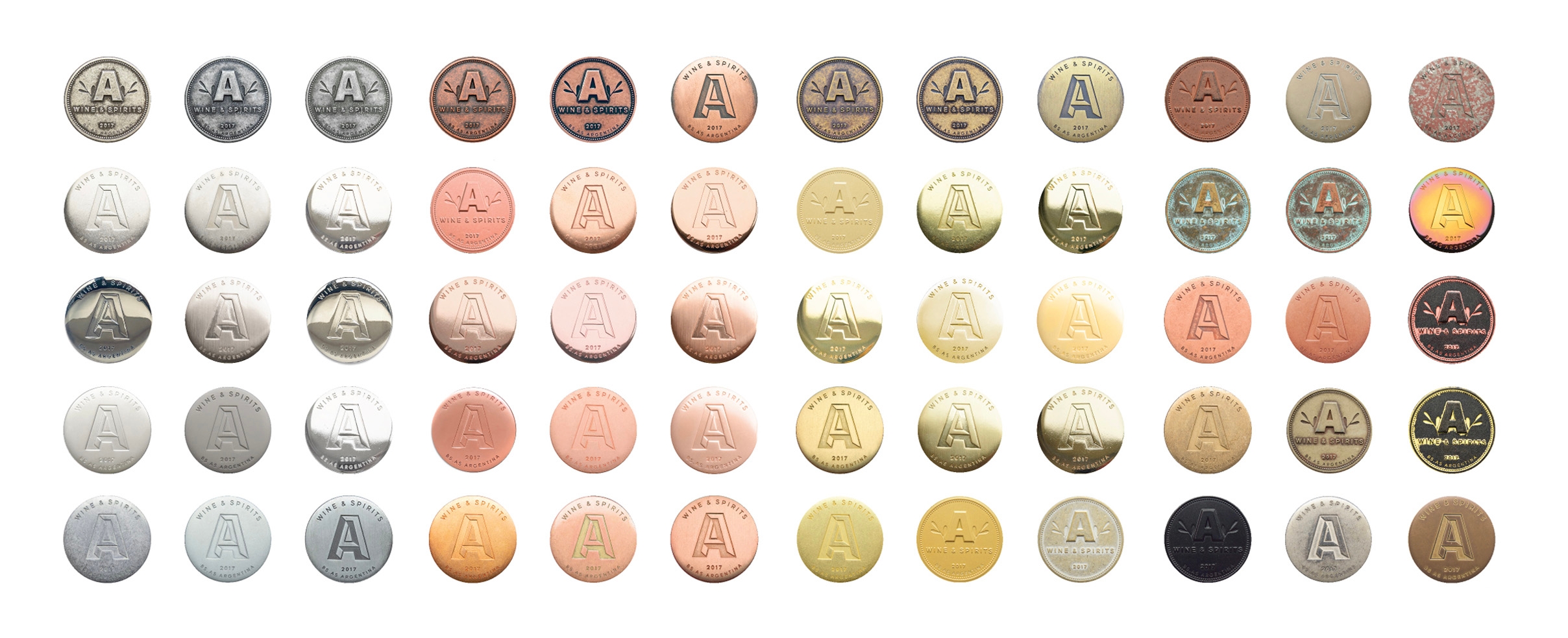

Surface color treatments

We offer over 300 galvanic colorways, including our exclusive vintage series with natural metal patina, ensuring each piece is unique.

We can also enamel-match KURZ, FOILCO, and PANTONE color systems.

Cork, GPI & Pourer System.

To ensure optional cork sealing, a fitting test is conducted before production to determine the best size and cork type. All supplied corks are certify food-grade, and every cork-stopper manufactered in our facility is ISO 22000 certified.

Our Commitment to the Environment:

We adhere to the highest standards of environmental compliance, using sustainable practices and materials that help reduce our carbon footprint.

Our goal is to offer luxury that doesn’t come at the expense of the planet.

• Eco-friendly Manufacturing: Our processes are designed to minimize waste and energy use.

• Recyclable Materials: Each stopper can be recycled, contributing to a circular economy.

ZERO-WASTE POLICY

In-house industrial production

How Apholos Stands Out

It is our offer to our clients, that includes:

Request more information

apholos.com